The cooling system is typically the most overlooked preventive maintenance item in a diesel engine. Proper cooling system maintenance is just as important as changing your oil. In fact, the condition of the coolant/anti-freeze in a diesel engine is even more important than in a gasoline engine. Crucial components on modern diesel engines like EGR coolers, and oil coolers rely on the condition and proper function of your cooling system.

Checking The Coolant

With the engine cooled down, make sure the coolant level is at the correct “Full” or “Max” line on the reservoir. If the level is low, you should add a 50/50 mixture of coolant & water. Some coolants are pre-mixed, so check the bottle to see whether you need to add water. Avoid using tap water to mix coolant as this could increase the risk of rust, corrosion, or scale. Instead, always use distilled or deionized water.

Coolant comes in a variety of different colors such as green, orange, red, yellow, or blue. If it looks colorless, rusty, or has things floating around in it, flush your cooling system and add new coolant. If the coolant has a sludgy, oily surface, immediately take the vehicle to your mechanic. It should be checked for a possible head gasket leak or other issues.

Coolant strength can be tested with test strips, a hydrometer, or a refractometer. The ideal mixture for your diesel’s coolant is 50 percent coolant and 50 percent water. The color, odor, and acidity of the coolant should be consistent with the original combination of fluids. This mixture should also be free of dirt or debris.

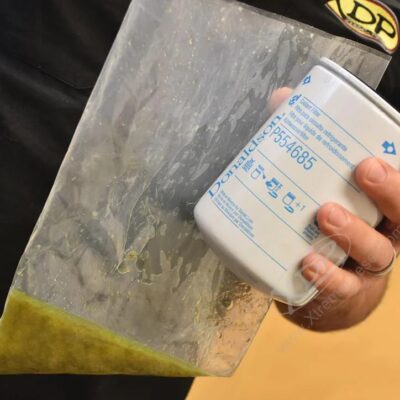

Test Strips

Paper test strips provide a simple and affordable way to check your coolant. Be sure to use strips specific to your type of coolant, and check the expiration date of the strips. With a simple dip, you can determine the nitrite level, freeze point, and pH level.

Hydrometer

A hydrometer is used to measure the specific gravity of coolant. This is basically a plastic tube with colored discs inside along with a squeeze bulb on top. The coolant is drawn into the test tube created by suction from the bulb. The object is to see how many discs will float once the coolant is drawn into the tube.

The degree of freeze protection is determined by how many discs float in the concentration of coolant. One variable in testing coolant this way is that the hydrometer can be temperature sensitive. A difference of up to 10°F can be seen if the coolant being tested is hot or cold. So make sure the vehicle’s coolant is around the same temperature every time you check it.

Refractometer

A refractometer measures the way light bends as it travels through an object, which in this case is coolant. This device is sometimes preferred because it is known to be more accurate, but it can also change with temperature.

Another benefit of the refractometer is the glass is wiped clean with each sample and will be more accurate. If the coolant being tested with a hydrometer has traces of oil in it, this can cause inaccurate readings. Once the oil has coated the discs, the hydrometer can read all other cooling systems wrong as well.

Coolant Maintenance Schedule

Make sure to check your owners manual and follow the recommended cooling system maintenance schedule. The recommended service interval for regular green coolant is around 2 years or 30,000 miles. For diesel engines running extended-life coolant, the service life is approximately 5 years or 100,000 miles. It is a good habit to test the coolant on a regular basis, in-between scheduled coolant changes.

If you’re using a conventional coolant or haven’t changed your coolant following the recommended schedule, it is a good idea to clean your system. This is achieved by draining and flushing the entire cooling system.

Radiator Cap & Hoses

One crucial often overlooked component of the coolant system is the radiator cap. When performing a periodic inspection, make sure the radiator cap is still functioning properly. Have the cap tested to make sure that the coolant system is maintaining the correct pressure and replace when needed. The cap is what maintains the coolant system’s pressure to prevent boil over.

The radiator hoses should also be inspected for cracks in the rubber or any leaks. Coolant hoses typically last several years, though anything older than 10 years should probably be replaced. Rubber can weaken with age and from repeated exposure to hot coolant. The older the hoses get, the higher chance they’ll start to leak.

Cavitation and the Ford Power Stroke

Cavitation is defined as a phenomenon in which rapid changes of pressure in a liquid lead to the formation of small vapor-filled cavities in places where the pressure is relatively low. This can exist in many diesel engines, but it is particularly common on some Power Stroke engines (with dry liners).

Combustion forces the cylinder wall to rapidly expand and contract creating vacuum bubbles in the engine coolant. These tiny bubbles slap into the cylinder wall and begin to do damage. Although it is an extremely minor force, it can eventually form a hole in the cylinder wall over time.

Supplemental Coolant Additive

Manufacturers counteract cavitation by requiring the use of an SCA/DCA (Supplemental Coolant Additive, Diesel Coolant Additive). These will not stop the formation of bubbles, but provide a protective barrier between the liner and the bubbles. This barrier is formed with the use of nitrite. The nitrite level will also need to be monitored on a regular basis. As the cavitation bubbles ping against the liner, they remove the layer of nitrite rather than the liner itself.

The ideal amount of nitrite in a diesel engine cooling system is around 800 ppm (parts per million). The cylinder liners can become compromised if levels drop below this level. Too much nitrite on the other hand is not always good either. Always follow the manufacturer’s recommended specifications.

If the nitrite level is between 300 ppm and 800 ppm, the anti-corrosion strength is considered low. Add Supplemental Cooling Additive as required. If the amount of nitrite is less than 300 ppm, the anti-corrosion strength is considered very low and cannot be restored. The cooling system will need to be flushed in this case. Test strips that tell the condition of coolant along with the level of nitrite are readily available.

Primary & Secondary Radiators

Some diesel trucks such as the 2011 and later Ford Super Duty trucks and the 2013-2014 Dodge Ram 2500/3500 feature dual radiators. These trucks feature two separate systems that work in parallel to handle all of the cooling needs.

Starting in 2011 Ford engineers began to incorporate dual radiators in the F-350, F-450, and F-550 trucks. These trucks feature two separate systems that work in parallel to handle all of the cooling needs. Each system uses its own coolant pump and they are almost completely isolated from one another.

The first more conventional system cools the engine by sending coolant through passages in the block and to a heat exchanger (or main radiator). This primary system also directs coolant to an oil cooler and the heater core. This system is similar to what is found on most other vehicles.

The secondary radiator, mounted in front of the primary, is responsible for the transmission cooler, the EGR cooler, the fuel cooler, and the intercooler. This system also has its own separate degas (overflow) bottle.

If your truck has two cooling systems then you will want to regularly monitor the coolant in both systems. Replace the coolant in both systems following the manufacturer’s service schedule. Many of these systems feature a plastic y-pipe that is prone to cracking. Upgrading to an aftermarket y-pipe constructed from billet aluminum will help eliminate this weak link.

Possible Reasons Your Diesel Is Overheating

1. Coolant

The most obvious cause of engine overheating is if there is any type of issue with the engine coolant. You should perform the following checks since the coolant is such a critical part of your diesel’s cooling system.

Again make sure there is enough coolant in the reservoir. A low coolant level could be an indication of a leak due to a loose clamp or damaged hose. This can also be a sign of more serious damage such as a crack in the engine or head gasket failure. Add more coolant and keep checking the fluid level and ground underneath your truck for signs of any leakage. If the coolant level continues to drop, but there are no signs of coolant leaks on the ground or from the exhaust pipe, there is a good chance the coolant is leaking into the crankcase and mixing with the oil.

Coolant In The Oil

In the event coolant loss is evident, but no leaks are visible, pull the oil dipstick and take a whiff. If you smell a sweet odor on the dipstick, odds are coolant is mixing with the engine oil. When coolant enters the crankcase shades of green, red, or orange can start to appear in the oil. This will depend on the type of coolant the vehicle uses.

Once the engine runs for any amount of time, however, the crankshaft and oil pump can have a blender-like effect. This will turn the oil and coolant mixture into what some refer to as a “milkshake” for obvious reasons. Another prominent indication of a coolant leak is white exhaust smoke that has a sweet odor. In this case, the dipstick oil level may actually rise. This can be an indication a significant amount of coolant has leaked into the crankcase.

Another reason that the coolant level is low is from air pockets or bubbles that formed in the cooling system. Air pockets can result during the refilling procedure and cause a restriction of fluid flow.

2. Malfunctioning Cooling Fan

A problem with the radiator fan or fan clutch will cause the engine to overheat. Inspect the fan and make sure it isn’t loose or broken. Replacing a faulty cooling fan is an easy solution to stop your engine from overheating. Other causes of the cooling fan not working properly are a defective coolant sensor or engine thermostat.

3. Water Pump

The water pump circulates coolant throughout the engine and cooling components. If the water pump pulley spins freely without any resistance, the water pump seals could be wearing out. An inspection of the water pump and pump housing can help identify any issues. Make sure to check the hoses for possible clogs preventing the proper flow of coolant.

Preventive Measures

Coolant Filtration Systems

Another popular upgrade for diesel trucks is Coolant Filtration Systems. Contaminants such as casting sand and sediment can damage components in your cooling system. Removing these contaminants helps to extend the life of your coolant, water pump, EGR cooler, and other vital components. These systems are easy to install and typically do not require any modifications to your factory hoses.

Coolant Additives

Another way to further enhance the performance of your cooling system is with a coolant additive. Additives are specially formulated to maximize the thermal transfer properties of your engine coolant to lower the temperatures. Not only does a coolant additive reduce engine coolant temps, but they also prevent build-up and corrosion. This helps extend the life of your cooling system and cooling system components.

Disclaimer: XDP is in no way affiliated with Cummins or any of its subsidiaries or related companies, and that Cummins has not authorized the sale of any of XDP’s parts, and has not tested or approved any of XDP’s parts for use in genuine Cummins brand products.